Aluminium Coil Coating Line

Why is it necessary to coated aluminium coil or plastics with an aluminium coating?

To prevent corrosion of items as well as aesthetics. The first continuous coil painting line, invented by Joseph Hunter, laid the groundwork for the subsequent development of industrial automation.

Smalls says it was a very cost effective way of painting metal.

So what are the main equipment and process of aluminum coil coating line?

I. Main coating equipment

1. Terminal equipment and aluminum coil coaters.

2. Metal treatment.

3. Primer/topcoat applicator.

4. Air cooling and water quenching; air cooling is used to reduce the strip PMT (peak metal temperature) to about 150-170 degrees Celsius.

5. Process control.

6. Tension straightener; this is where a high degree of control is required and aluminum color coated coils can be as light as 0.18mm (equivalent to 0.06mm steel).

7. Chemical coating machine.

8. Main/finish drying box.

9. Hot/cold laminators; can increase the advantages of material stiffness

10. Installation service.

What are Metal Shredders and How Do They Work?

Do you know the advantages of lintel making machine

Cooled Water Chillers vs. Air-Cooled Chillers: Comparing Options

What is the advantage of telescopic boom lift?

What does a bucking unit do?

Choosing the Perfect Double Shaft Paddle Mixer for Your Needs

How Does a Mobile Asphalt Plant Work?

II. Coil coating process flow

1. Production management of pre-treatment stage of coating line.

Aluminum coils must be surface treated to remove oil and rust before powder coating. There are more chemicals used in this stage, mainly rust remover, degreasing agent, table conditioning agent, phosphating agent, etc.

2. Powder coating

Ensure that the sprayed aluminum rolls are evenly powdered and of uniform thickness to prevent defects such as thin spraying, leakage spraying, rubbing off, etc. Before entering curing, the powder attached to it should be blown off as far as possible to facilitate uniform powdering of aluminum rolls.

3. Heating curing

Baking in strict accordance with the process and temperature and time control, pay practical attention to prevent color difference, over-baking or too short a time caused by insufficient curing.

4.Final installation and transportation

Characteristics of LITONG aluminum coil coating line

1. Adopt high precision roll coating machine, excellent coating quality.

2. Suitable for acrylic, polyester, and polyvinylidene fluoride (PVDF) coatings.

3. Specifically designed to fit the area of the customer's plant.

4. Fine coating in accordance with international standards.

5. Easy to operate controls, online operator training available.

In short aluminum color coating provides a versatile product for the construction industry. Incorrect line design can lead to high scrap rates or inability to handle the full range of products, resulting in far lower production yields and incalculable losses, choosing the right coating line plant and aluminum coil coating machinery is critical for your painted aluminium coils. Please feel free to contact us to discuss your requirements.

Additional resources:The Differences Between Barrel and Rack Plating

The Benefits of Using Blow Molding Machines

What is the difference between a boom lift and a spider lift?

What is a cableway used for?

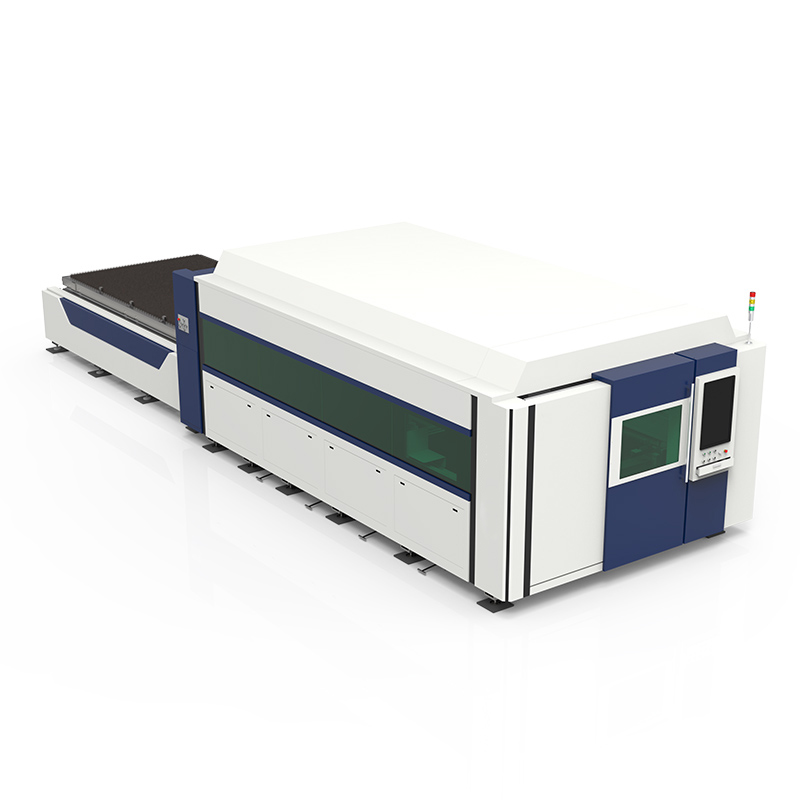

How much does a fiber laser cutter cost?

What is a fiber laser cutting machine used for?

What is a conveyor roller used for?