Troubleshooting Common Chiller Problems and Solutions Guide

Learn about the most common problems and solution guides when troubleshooting chillers here. There are 3 main problems as follows.

1. Clogging problems

2. High pressure system problems

3. Temperature system problems

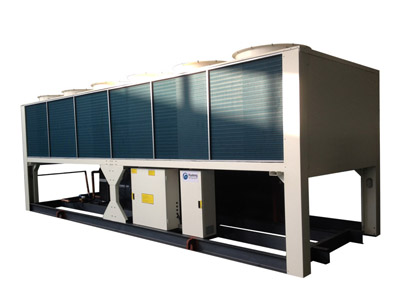

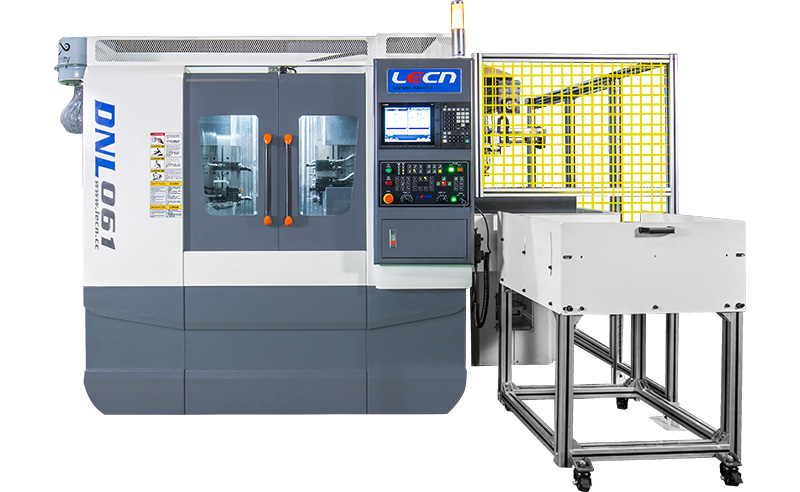

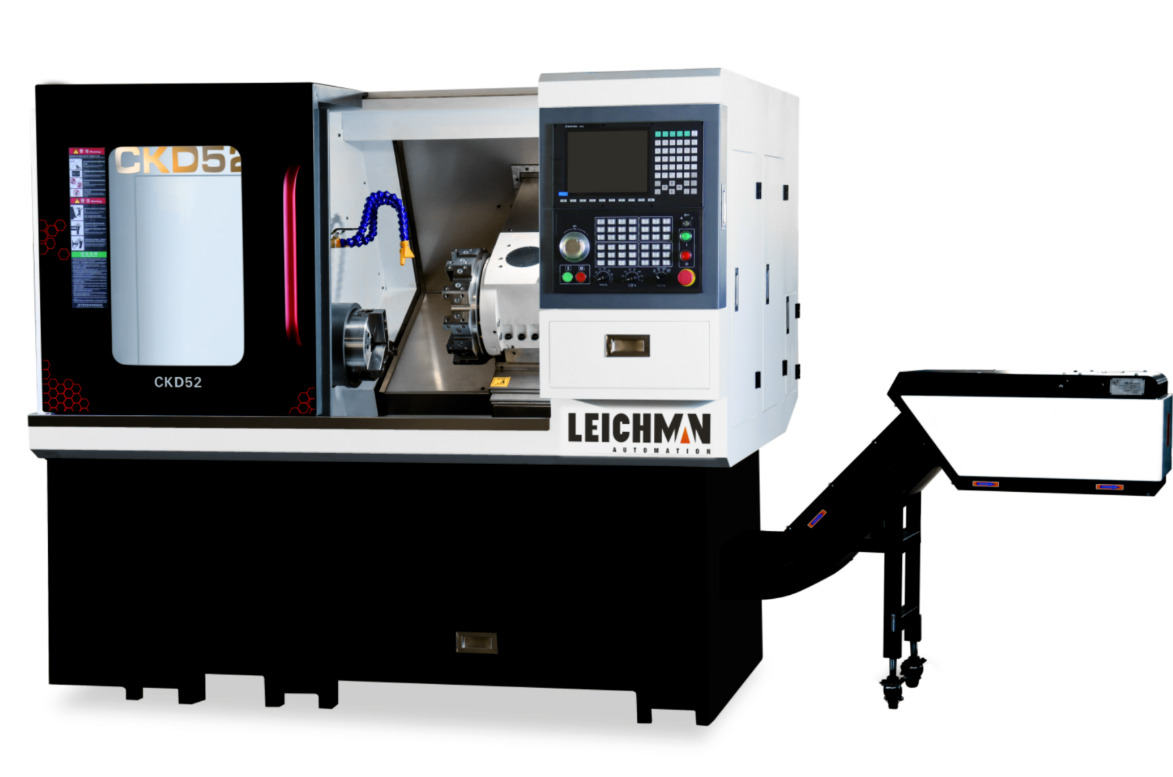

Related products

A. Clogging problem

Failure due to oil clogging

The main reason for oil clogging:

The compressor cylinder body wears heavy or cylinder with too large clearance. With the compressor discharge gasoline into the condenser is discharged, and then with the refrigerant into the filter drier, because the oil viscosity is greater, through the filter desiccant blockage, too much oil into the filter inlet blockage, so that the refrigerant can not circulate normally.

In the water chiller system remaining too much refrigerant oil, so that the effect of cooling, and also can not be cooling, so the system must be cleared of refrigerant oil.

Oil clogging treatment:

Filter oil clogging should be replaced with a new filter, while using high-pressure nitrogen gas to the condenser part of the accumulation of refrigerant oil, preferably in the passage of nitrogen gas, using an electric hair dryer to heat the condenser.

Hazards of oil film.

When the surface of the heat exchanger attached to the oil film, condensing temperature rises, evaporating temperature decreases, resulting in increased energy consumption.

When the condenser surface attached to 0.1 mm thick oil film, the refrigeration compressor cooling capacity decreased by 16%, power consumption increased by 12.4%.

When the evaporator oil film reaches 0.1mm, the evaporating temperature decreases by 2.5℃ and the power consumption increases by 11%.

How to solve the oil film problem?

Using high efficiency oil separator can greatly reduce the amount of oil entering the system pipeline. If oil film is already present in the system, several nitrogen flushes can be performed until no mist is Display.Contact us to get more information.

Errors caused by ice blockage

The icing fault is mainly because the chiller contains too much water. With the continuous circulation of refrigerant, the water in the chiller gradually concentrates at the throttle, and as the temperature at the throttle is the lowest, the water turns into ice and gradually becomes cold. A certain degree will completely block the capillary tube and the refrigerant cannot be circulated.

Main sources of moisture.

Residual moisture in chiller system components and connecting piping due to inadequate drying.

Refrigerant oil and refrigerant containing more water than allowed.

Moisture present due to installation construction without vacuum or improper installation.

Additional resources:How does oil extraction machines work?

Inline Plastic Scrap Granulator: A Revolutionary Solution for Plastic Waste Recycling

X-ray Counter: Revolutionizing Medical Imaging

Enhancing Efficiency and Precision: The Advantages of CNC Pipe Threading Lathes

Understanding the Pricing Factors of Portable Pipe Cutting Machines

Unlocking Precision and Efficiency: How Fiber Laser Cutting Machines Work

Mushroom Grinding Machine: Revolutionizing the Processing Industry

Moisture in the insulation paper of the motor inside the compressor.

Manifestations of ice jams:

Gradual weakening and interrupted airflow.

The sound of airflow disappears when the blockage is severe, the refrigerant circuit is interrupted and the condenser gradually becomes cooler.

Increase of exhaust gas pressure and operation noise of the machine due to clogging.

No refrigerant flows in the evaporator, the frost area becomes smaller gradually and the cooling effect becomes worse.

After stopping the machine for some time, the refrigerant begins to produce again (cold ice begins to melt).

The ice blockage forms a moment to pass, a moment to block, block and pass, pass and block the cycle of repetition.

How to solve the problem in case of ice blockage?

Ice blockage failure in the chiller is due to excessive moisture in the system, so the entire refrigeration system must be dried out. The treatment method is as follows. Evacuate, replace the filter drier, the moisture indicator in the refrigeration system will qualify the apparent level to green.

If there is a lot of water in the system, we should use nitrogen to flush the dirt in sections, replace the filter, change the refrigerant oil, replace the refrigerant and evacuate until the water indicator in the sight glass turns green.

Water Cooled Scroll Chiller

Errors due to dirty clogging

The chiller is dirty blocked because the refrigerant can't circulate, so the compressor runs continuously, the evaporator is not cold, the condenser is not hot, the compressor shell is not hot, and there is no airflow sound listening to the evaporator. When there are more impurities in the system, the filter drier is gradually blocked, and the flow blocking mechanism filter is blocked.

Main causes of dirt clogging:

Construction and installation of dust and metal fries, pipe welding when the inner wall surface oxide layer off.

The internal and external surfaces are not cleaned when the parts are processed, the pipes are not sealed tightly and dust enters the pipes.

Impurities in refrigeration oil and refrigerant, poor quality desiccant powder in filter drier.

The distance between the capillary tube and the filter in the filter drier is too small, causing dirty blockage.

Performance after dirty clogging:

A cool or cold feeling in the evaporator when it is partially clogged, but no frost.

The cool feeling when touching the outer surface of the filter dryer and choke, even when frost.

The evaporator is not cold, the condenser is not hot, compressor housing is not hot.

How to solve the dirty clogging?

Dirty clogging is usually at the filter drier, choke mechanism mesh filter, suction filter, etc. The filters of the choke mechanism and suction filter can be removed and cleaned, and the filter drier is generally replaced. After the replacement is completed, the chiller needs to be leak tested and vacuumed.

Fixed Towing Cableways as a Transport Solution

How Do I Choose the Right Low-Pressure Injection Molding Machine for My Needs?

Air-Cooled Screw Condensing Units

What Is an Excavator Vs Backhoe?

How Does an Induction Brazing Machine Work?

What is Common Blow Molding Problems and Solutions?

Why is a Thermal Inkjet Printer a Popular Choice for Small Businesses and Home Offices?