Low Alloy U Bend Tube: Superior Strength & Flexibility

In an increasingly competitive global market, industries are focused on advancing technology and materials to enhance efficiency, reduce costs, and ensure durability. Among the pivotal developments in material engineering are low alloy U bend tubes, which are becoming essential components across various applications, including oil and gas, power generation, and chemical processing. This report explores the advantages of low alloy U bend tubes, current market hotspots, and emerging trends that could redefine industry standards.

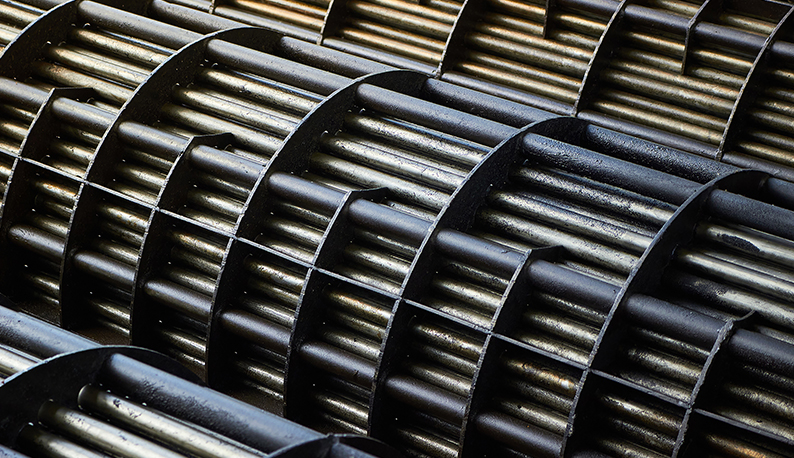

What are Low Alloy U Bend Tubes?

Low alloy U bend tubes are uniquely shaped tubular components, designed to perform efficiently under varying pressure and temperature conditions. Constructed from a blend of alloys—primarily steel with additional elements like chromium, nickel, and molybdenum—these tubes offer exceptional mechanical properties, corrosion resistance, and overall durability.

Advantages of Low Alloy U Bend Tubes

- Superior Strength: The alloy composition of U bend tubes enhances their strength, allowing them to withstand high pressure and temperature without significant deformation.

- Flexibility: Their unique U shape provides greater flexibility in design and installation, making them suitable for various applications where space is limited.

- Corrosion Resistance: The presence of chromium and other alloying elements improves resistance to corrosion, especially in harsh environments.

Applications in Various Industries

Low alloy U bend tubes are versatile and find application in several industries:

- Oil and Gas: Used in various components such as heat exchangers and pipelines.

- Power Generation: Essential in steam and gas turbines, providing efficient pathways for fluids.

- Chemical Processing: Employed in reactors and lines where chemical resistance is paramount.

Market Trends

The demand for low alloy U bend tubes is on the rise, driven by the need for efficient and durable materials in manufacturing. Key trends include:

- Innovative Alloys: Ongoing research into new alloy compositions aims to further enhance performance characteristics.

- Sustainability Focus: Companies are looking for materials that not only perform but also minimize environmental impact during production and use.

- Customization: Increasing demand for customized solutions tailored to specific requirements across industries.

Conclusion

Low alloy U bend tubes represent a significant advancement in material engineering, offering a balance of superior strength and flexibility. As industries continue to evolve, the importance of these components will only grow, making them foundational to modern manufacturing processes. Keeping an eye on market trends and technological innovations will be crucial for stakeholders involved in the production and application of low alloy U bend tubes.