Top Tips for Maximizing Your Pet Treats Extrusion Line

Pet treats are beloved by our furry friends, and the demand for high-quality treats continues to soar. As a pet treat manufacturer, ensuring efficiency and excellence in production is paramount. That's where a Pet Treats Extrusion Line comes in. In this comprehensive guide, we'll explore everything you need to know about optimizing your Pet Treats Extrusion Line for maximum output and quality.

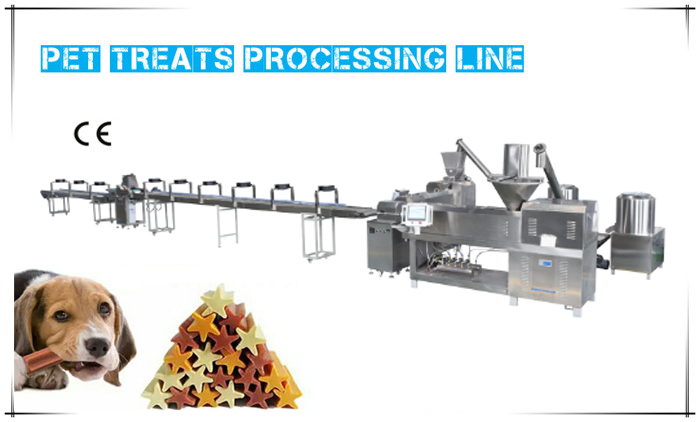

What is a Pet Treats Extrusion Line?

A Pet Treats Extrusion Line is a sophisticated machinery setup designed to efficiently produce a variety of pet treats through the process of extrusion. This innovative system enables the creation of different shapes, sizes, and textures, catering to various preferences among pets and their owners.

Components of a Pet Treats Extrusion Line

The Pet Treats Extrusion Line comprises several key components, each playing a crucial role in the production process:

Extruder: The heart of the system, where raw ingredients are mixed, cooked, and formed into the desired treat shapes.

Die Plates: These molds determine the final shape and size of the treats.

Cutting Mechanism: Responsible for cutting the extruded treats into uniform pieces.

Dryer: Removes moisture from the treats, enhancing shelf life and preserving freshness.

Coating or Flavoring Unit: Applies coatings or flavors to enhance palatability.

Benefits of Using a Pet Treats Extrusion Line

Investing in a Pet Treats Extrusion Line offers numerous advantages:

Efficiency: Streamlined production process reduces labor and time requirements.

Consistency: Ensures uniformity in treat size, shape, and texture.

Customization: Allows for the creation of tailored treats to meet specific dietary or flavor preferences.

Scalability: Easily adjust production volumes to meet changing market demands.

What is the principle of double cone rotary vacuum dryer?

Optimizing Your Pet Treats Extrusion Line

Maintaining Optimal Operating Conditions

To achieve peak performance from your Pet Treats Extrusion Line, it's essential to:

Monitor Temperatures: Maintain precise temperature control throughout the extrusion process to ensure proper cooking and texture.

Regular Maintenance: Schedule routine maintenance checks to identify and address any issues promptly.

Quality Ingredients: Use high-quality raw materials to produce treats that meet nutritional standards and delight pets.

Ensuring Product Quality

Quality is paramount when it comes to pet treats. Here's how to uphold it:

Quality Assurance Protocols: Implement rigorous quality control measures at every stage of production to uphold consistency and safety.

Testing Procedures: Conduct regular product testing for attributes like taste, texture, and shelf life to maintain high standards.

Customer Feedback: Listen to customer feedback to identify areas for improvement and refine your product offerings accordingly.

Maximizing Efficiency and Output

Efficiency is key to profitability. Consider these strategies:

Production Planning: Develop a comprehensive production schedule to optimize resource utilization and minimize downtime.

Training Programs: Invest in training for operators to ensure they are proficient in operating the equipment and troubleshooting common issues.

Automation Integration: Explore opportunities to automate certain processes to increase throughput and reduce labor costs.

Conclusion

A Pet Treats Extrusion Line is a game-changer for pet treat manufacturers, offering unparalleled efficiency, flexibility, and product quality. By understanding the components, optimizing operations, and prioritizing quality, you can unlock the full potential of your pet food extrusion line and delight pets and their owners alike with delicious and nutritious treats.