How Does a Vertical Slurry Pump Work?

Vertical slurry pumps are specialized pumps designed to handle abrasive and corrosive slurries with efficiency and reliability. Unlike their horizontal counterparts, which are commonly used for clean fluids, vertical slurry pumps are engineered to withstand the challenges posed by abrasive mixtures containing solid particles.

How Does a Vertical Slurry Pump Work?

At the heart of a vertical slurry pump is the impeller, a rotating component that accelerates the slurry and directs it into the pump's casing. As the slurry enters the casing, the specially designed vanes of the impeller impart energy to the mixture, enabling it to flow upward. This vertical design allows the pump to effectively transport the abrasive slurry from the sump or pit to its destination.

Key Components and Design Features

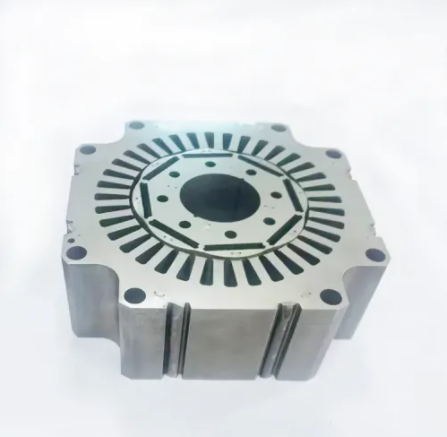

Impeller Design

The impeller of a vertical slurry pump is meticulously crafted to handle abrasive particles. It is often equipped with hardwearing materials or a rubber lining to resist wear and extend the pump's lifespan. The impeller's design plays a crucial role in maintaining hydraulic efficiency and minimizing clogging.

Additional resources:How Do I Know If My Truck Bearings Are Bad?

What is the difference between spherical and cylindrical roller bearings?

What is a limit switch?

Rothwell, Figg, Ernst & Manbeck, P.C. - JDSupra

List of Valves: 10 Types of Valves

Guide to Selecting a CAN bus Display

High-Pressure Quick Connect Nozzle Spray Gun: The Ultimate Tool for Efficient Cleaning

Casing and Housing

The casing of a vertical slurry pump is built to endure the erosive forces of abrasive slurries. It is typically constructed from high-grade materials that can withstand corrosion and impact. The casing's unique design also contributes to efficient flow dynamics.

Shaft Seal Mechanisms

To prevent leakage and ensure the pump's longevity, effective shaft sealing mechanisms are employed. These mechanisms include various sealing options such as mechanical seals, gland packing, and dynamic seals, each tailored to specific operating conditions.

Stay tuned for the rest of the article, which will cover the applications, advantages, maintenance, and selection of vertical slurry pumps.

Vertical slurry pumps stand as reliable allies in managing abrasive mixtures across diverse industries. Their space-saving design, resilience against wear, and cost-effective maintenance make them a vital asset for fluid handling. By understanding their applications, advantages, and maintenance techniques, you can harness the power of vertical slurry pumps to elevate your operational efficiency.

Additional resources:The Essential Guide to Overhead Conveyor Bearings: Everything You Need to Know

The Benefits of Using Activated Carbon Filters in Your Home

Drum Gear Coupling: The Backbone of Efficient Power Transmission

Selecting the Right Slurry Pump or Sand Dredge Pump

Benefits of Three Phase Hybrid Inverters

Factors to Consider Before Choosing an Overhead Block Clamp

What are Antigravity Motors?