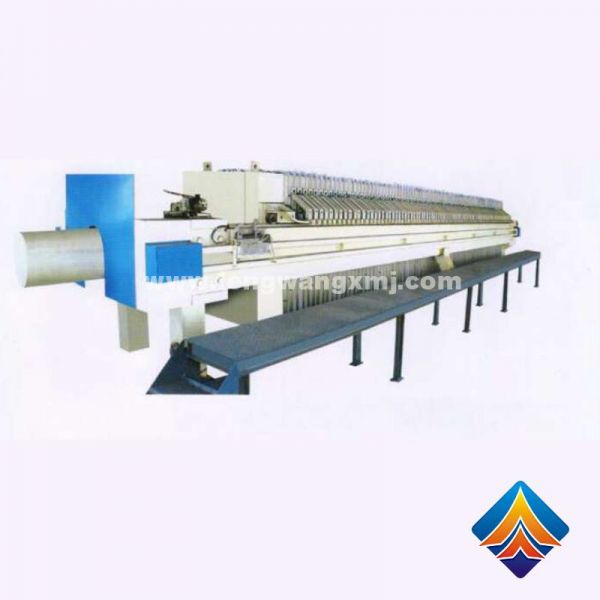

Chamber Filter Press: A Versatile and Efficient Filtration Solution

Filtration is a critical process in various industries, such as chemical, pharmaceutical, mining, and wastewater treatment. It involves separating solid particles from liquids or suspensions, which can be challenging and time-consuming. That's where the Chamber Filter Press comes in, as it offers a versatile and efficient solution for high-capacity filtration needs.

What is a Chamber Filter Press?

A Chamber Filter Press (CFP) is a type of filter press that uses a series of rectangular chambers, or plates, to separate solids from liquids. The plates are made of reinforced polypropylene or cast iron and are arranged in a stack, with a filter cloth or mesh between each plate. The plates are hydraulically or manually pressed together to create sealed chambers that trap the solids while allowing the liquids to pass through the filter media.

How Does a Chamber Filter Press Work?

The operation of a CFP involves several steps that depend on the characteristics of the feed and the desired product. Generally, the process starts by filling the chambers with the slurry, which can be pre-treated with chemicals or flocculants to enhance the separation. Then, the plates are compressed, and the liquid phase is expelled through the filter media and collected in a receiving tank or discharge outlet.

Once the filtration is complete, the plates are opened, and the dry solids are removed manually or automatically using a scraper or conveyor. The filtrate can be further processed or discarded depending on its quality and the application.

What are the Advantages of Chamber Filter Press?

The Chamber Filter Press offers several advantages over other filtration methods, especially for large-scale or continuous operations. Some of these advantages include:

High capacity: CFPs can handle large volumes of slurry with high solids content, making them ideal for industrial applications.

Efficient separation: CFPs can achieve high separation efficiency, with low residual moisture in the solids and high purity in the filtrate.

Versatility: CFPs can be used for various types of feeds, including solids, liquids, and sludges, and can accommodate different filter media and operating conditions.

Additional resources:How Do I Choose a Packing Machine?

Universal Spline Hobbing Machine: Shaping Precision Gears

Impact Crushers vs. Jaw Crushers: Which Is Right for Your Crushing Needs?

Advantages of Chicken Chips Forming Machine

Why Are Essential Oils Stored in Dark Glass Bottles?

What is a Drilling Rig and Why is it Used?

Are EVI DC Heat Pumps environmentally friendly?

Automation: CFPs can be equipped with various automation features, such as sensors, timers, and control panels, to optimize the filtration process and reduce labor and downtime.

Cost-effectiveness: CFPs offer a cost-effective solution for high-capacity filtration needs, with low energy consumption, minimal maintenance, and long service life.

Applications of Chamber Filter Press

CFPs are widely used in various industries for separating solids from liquids or suspensions, including:

Chemical processing: CFPs are used for clarifying, dewatering, and refining chemical products such as pigments, resins, and polymers.

Mining and mineral processing: CFPs are used for extracting, concentrating, and dewatering minerals such as gold, silver, copper, and iron.

Pharmaceutical and biotech: CFPs are used for purifying, sterilizing, and filtering drug substances, vaccines, and biologics.

Food and beverage: CFPs are used for clarifying and dewatering food and beverage products such as beer, wine, juice, and dairy.

Wastewater treatment: CFPs are used for sludge dewatering, biosolids processing, and effluent polishing in municipal and industrial wastewater treatment plants.

Conclusion

The Chamber Filter Press is a versatile and efficient filtration solution that offers several advantages over other methods. It can handle high-capacity feeds with high solids content and achieve high separation efficiency with low residual moisture and high purity. It is widely used in various industries for separating solids from liquids or suspensions and can be equipped with automation features

Powering Progress: Advantages and Applications of Slip Ring Induction Motors

Understanding the Chill: Exploring the Difference Between AC and Chiller Systems

Which is the Better Transportation Method: Cable Car or Ropeway?

How does a fixed grip chairlift work?

What are the parts of aerial work platform?

Unlocking the Secrets of Radiation Measurement Instruments: How Do They Work?

What are the applications of electric wheel loaders?