What Are Stator and Rotor Cores and How Do They Work in Electric Motors?

Electric motors are essential components in many modern machines, from household appliances to industrial equipment. One of the key elements that make electric motors work is the stator and rotor core. In this article, we'll explore what stator and rotor cores are, and how they function in electric motors.

What Are Stator and Rotor Cores?

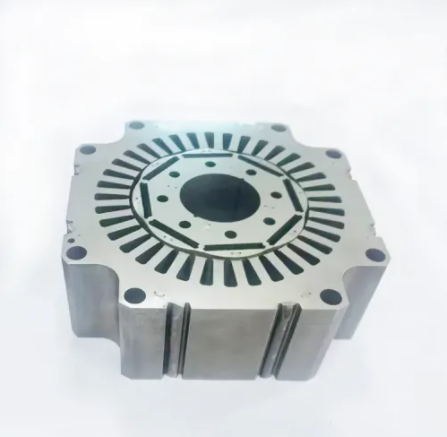

Before we dive into how they work, let's define what stator and rotor cores are. The stator is the stationary part of an electric motor, which surrounds the rotor. It typically consists of a cylindrical frame made of laminated steel, which contains a series of evenly spaced slots. These slots are filled with copper wire windings, which are used to create an electromagnetic field when an electric current flows through them.

The rotor, on the other hand, is the rotating part of the electric motor, which sits inside the stator. It also consists of a laminated steel core, which is formed into a cylindrical shape. The rotor typically has a shaft that extends from both ends of the core, which allows it to rotate freely within the stator.

How Do Stator and Rotor Cores Work in Electric Motors?

Electric motors work by using the interaction between the stator and rotor cores to produce rotational motion. When an electric current is applied to the windings in the stator, it creates a magnetic field that rotates around the stator. This magnetic field then interacts with the magnetic field created by the rotor, causing it to rotate.

Related links:Mechanical Parts & Fabrication Services

The Benefits of Investment Casting

How precise is investment casting?

How Do I Choose the Right Oil Seal Kit?

Differences between Cast Steel and Forged Steel Valves

What are miniature bearings used for?

Benefits of Electric Diaphragm Pumps

The way this interaction occurs is through the principle of electromagnetic induction. As the magnetic field from the stator rotates around the rotor, it induces a current in the rotor windings. This current then creates its own magnetic field, which interacts with the stator's magnetic field, causing the rotor to rotate.

The number of poles in the stator and rotor cores determines the speed at which the motor rotates. The more poles that are present, the slower the motor rotates. For example, a four-pole motor will rotate at a speed of 1,800 revolutions per minute (RPM) when connected to a 60-hertz power source, while an eight-pole motor will rotate at 900 RPM under the same conditions.

Conclusion

In conclusion, stator and rotor cores are critical components in electric motors that work together to produce rotational motion. The stator consists of a laminated steel core with copper wire windings that create an electromagnetic field, while the rotor is a laminated steel core that rotates within the stator. The interaction between the magnetic fields created by the stator and rotor is what drives the rotational motion of the motor. Understanding the basics of stator and rotor cores is essential for anyone who wants to understand how electric motors work.

If you are finding Stator and Rotor Lamination Welding Service, we will be your best choose! we have our own factory, so we can give you a cheap price!

Additional resources:Which is better CV joints or universal joints?

Where is tyre coupling used?

How to Achieve Gear Coupling Reliability

How Reliable Are Caterpillar Diesel Engines?

What are the main three functions of a directional control valve in a hydraulic circuit?

What is a Mechanical seal?

How to Choose the Right Sump Pump?